39 workplace labels must be put in place

Workplace Label - WorkSafeBC WorkSafeBC WHMIS 2015: The Workplace Label The workplace label is one of the two main types of WHMIS labels. This toolbox meeting guide discusses when workplace labels are needed, the information they need to show, and the formatting guidelines for these labels. This guide also describes two specific cases in which workplace labels are not needed. A Guide to OSHA's New GHS Chemical Labeling Requirements Since alternative labeling requirements may change in fewer than 4 years and employers must train employees to understand new label elements and the new Safety Data Sheet (SDS) format by Dec. 13, 2013, voluntarily switching to the revised HCS labeling now likely will reduce costs over the long run and reduce confusion in the workplace.

DOT Labeling Requirements: When Does a Hazmat Package Need Labels? If you have to label for both a primary and a subsidiary hazard class or divisions, these labels must be displayed next to each other within 6 inches (150mm). If you don't know where to find the materials primary and subsidiary hazard class, go the the 172.101 hazmat table and look at column 6. You can find the table here. Duplicate labels

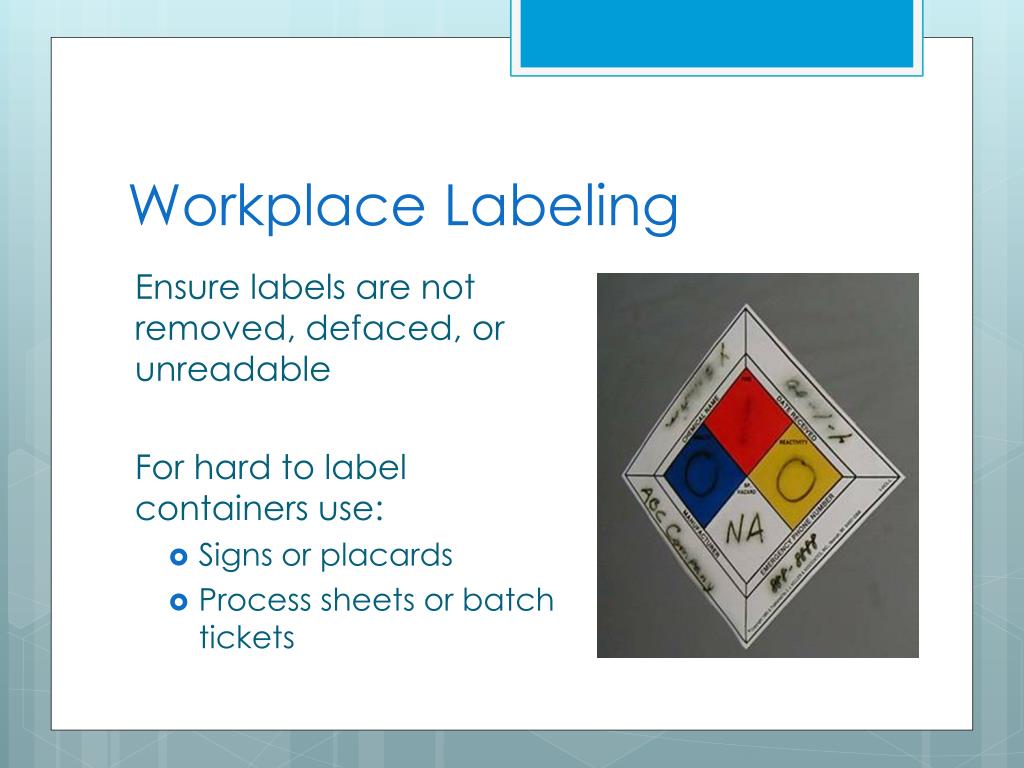

Workplace labels must be put in place

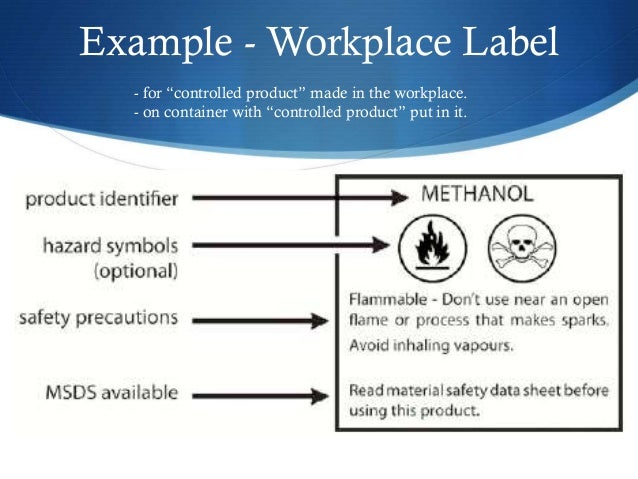

4.7 - Workplace labels | WHMIS 2015 - University of Ottawa created in the workplace, received without a supplier label or transferred into a container that had no labelling. Workplace labels do not require a border or specific wording; they do, however, require the following information: Product identifier (product name matching that on the SDS), Information for the safe handling of the product, and Mandatory OSHA Posters and Signs - Safety Blog | Safesite OSHA regulates most workplaces and requires safety signs at most locations where a hazard threatens the safety of a worker. Each safety sign is classified by hazard risk to help determine what sign to use, including DANGER, WARNING, and CAUTION. Implement these key safety sign formats to meet OSHA requirements for safety signage. DANGER PDF Workplace Labeling Requirements - Concordia University There are four (4) situations when workplace labels are required: 1. A hazardous product is produced (i.e., synthesized or prepared) and will be used on-site by several individuals and will be stored for a long period of time or will leave the workplace. It must be stocked in a suitable (chemically compatible) container.

Workplace labels must be put in place. WHMIS 2015 - Labels : OSH Answers A workplace label is required when: a hazardous product is produced (made) at the workplace and used in that workplace, a hazardous product is decanted (e.g., transferred or poured) into another container, or a supplier label becomes lost or illegible (unreadable). There are two situations when a workplace label is not necessary. Five Ways to Meet OSHA Requirements for Safety Signage 29 CFR 1910.145 (f) (4) requires the sign's signal word—"Danger," "Caution," etc.—to be readable from at least five feet away. Broadly speaking, signs should be placed such that workers are aware of the hazard and able to respond appropriately before being exposed to it. The Sign Itself Should not Cause a Hazard. Information Elements Required on a WHMIS 2015 Label An importer could retain the name of the foreign supplier if the hazardous product is imported for the importer's use in its own workplace in Canada. The supplier identifier on the label must match the supplier identifier provided on the SDS. ABC Chemical Co. 123 Anywhere St. Mytown, ON N0N 0N0 (123) 456-7890: Supplemental Information Labeling of Secondary Containers - Occupational Safety and Health ... section 1910.1200 (f) (6) (ii) requires that workplace labeling include "product identifier and words, pictures, symbols, or combination thereof, which provide at least general information regarding the hazards of the chemicals, and which, in conjunction with the other information immediately available to employees under the hazard communication …

Top 10 Safety Rules in the Workplace Wear suitable personal protective equipment - This will help to protect you from workplace injuries and accidents. Safety boots must be used in workshops. Safety glasses are required to protect your eyes in job sites. Keep your workplace clean and tidy - Store tools, equipment, and supplies should be kept properly when not in use. Putting the Right Signs in the Right Places - Occupational Health & Safety Consider these commonly used labels and signs: Pipe markers Equipment marking Tank and vessel signs Right-To-Know labels Lockout/tagout labels and tags Aisle and floor marking Safety... Work Health and Safety (Labelling of Workplace Hazardous Chemicals ... A label must identify those ingredients, including their proportions, which contribute to the overall hazard class and hazard category of the hazardous chemical in accordance with Schedule 8 of the WHS Regulations. ... The person conducting a business or undertaking at the workplace must also ensure that a container labelled for a hazardous ... Compliance FAQs: Packaging and Labeling in the US | NIST There are many regulations, depending on the product, with which a product's label or markings must be in compliance before being sold in the United States. Labeling requirements related to legal metrology (i.e., products and commodities sold in package form by weight, measure or count) must comply with The Fair Packaging and Labeling Act ...

Requirements for labeling of products shipped for export to domestic ... However, as OSHA explained in its November 23, 2015, letter to Mr. Stephen Wieroniey (copy enclosed), an HCS 2012 label compliant with paragraph 1910.1200 (f) (1) must be on the outside of the shipping container or attached to any accompanying shipping papers or bill of lading. Labeling Requirements | US EPA Labeling Requirement Resources. The Label Review Manual - The goal of the Label Review Manual is to improve the quality and consistency of labels. The manual can be useful for state label reviewers, registrants and other individuals interested in producing readable, unambiguous pesticide labels. Pesticide Product Labels - The information on ... Container Labeling: A Key to Compliance - Occupational Health & Safety After deciding on a format for labeling, employers should designate someone with the responsibility of ensuring containers are properly labeled, information on labels is reviewed periodically, and... Safety Signs and Labels - OSHA Compliant and Specifications - SafetyInfo The message and safety symbols should be printed in green or black on a white background. The signs may also be printed in white on a green background. These signs should never include the safety alert symbol. Fire Safety signs are used to indicate the location of emergency fire fighting equipment. Unlike other signs, they do not require a header.

GHS Labeling Requirements: The Definitive Guide [2021 Update ... - Luminer However, the GHS takes into consideration that, sometimes, it's not possible to keep workers safe with only these six label requirements, which is why it also allows for supplemental information. 1. Product Identifier. This requirement identifies the actual hazardous chemical inside the container.

Guidance for General Laboratory Safety Practices during the COVID-19 ... General Guidance. This guidance is to address the general safety concerns of laboratory personnel during the COVID-19 pandemic. All laboratories should perform site- and activity-specific risk assessments to determine the most appropriate safety measures to implement for particular circumstances. In addition, facilities should adhere to local ...

WHMIS 1988 - Labelling Requirements : OSH Answers "Where, in a work place, a label applied to a controlled product or a container of a controlled product becomes illegible or is removed from the controlled product or the container, the employer shall replace the label with a work place label that discloses the following information in respect of the controlled product (a) the product identifier;

Hazard Communication - Container Labeling - OSHAcademy Types of Containers. Container labeling is a very effective method to communicate the physical and health hazards of chemicals used in the workplace. The information on a container label will vary depending on what type of container it is and how it is used. We'll discuss labeling requirements under the HCS 2012 (also referred to as GHS ...

Industrial Safety Signs Guide: Types, Standards, Regulations - MPC Danger Signs - Must be red, black, and white. Caution Signs - Must have a yellow background color with black lettering for any elements used against the yellow background. The panel must be black with yellow letters. Safety Instruction Signs - Must have a white background, and the panel must be green with white letters.

PDF GUIDE FOR EMPLOYERS AND WORKERS Workplace Labels - WSCC 4REFERENCE TO SDS If available. GENERAL LABELLING REQUIREMENTS Convey workplace labels in a manner that is appropriate to the workplace, including meeting language requirements. Labels must be easy to read and durable. If the label is lost, damaged, or no longer readable, the product must be relabelled.

Intro to Hazard Communication, Part Three: Labeling Requirements If you consistently work with specific chemicals in your operations and place them in workplace containers, you can buy secondary containers from certain industrial supply stores that come with pre-affixed labels containing the chemical name and other hazard communication elements, such as pictograms.

Workplace Safety Procedures - Workplace Safety in the Foodservice Industry Never work while under the influence of drugs or alcohol, as you are a hazard to yourself and your co-workers. Pay particular attention to moving objects, such as equipment, dollies, mixers, and slicers. Walk, do not run, in the work areas. Stay completely alert on the job. Avoid back strain by lifting properly.

Proper Labeling Chemical Containers - OSHA Review The secondary label must include product identifier and words, pictures, symbols, or combination thereof, which provide at least general information regarding the hazards of the chemicals, and which will provide employees with specific information regarding the hazards of the chemicals.

WHMIS Workplace Labeling - Environmental Health & Safety A workplace label is not required if the worker who transferred the hazardous chemical will use up the chemical on the same day it was transferred. Non-hazardous chemicals do not require a workplace label. Salt solutions, phosphate buffers and broths would typically not be considered hazardous, and therefore would not require a workplace label.

PDF Workplace Labeling Requirements - Concordia University There are four (4) situations when workplace labels are required: 1. A hazardous product is produced (i.e., synthesized or prepared) and will be used on-site by several individuals and will be stored for a long period of time or will leave the workplace. It must be stocked in a suitable (chemically compatible) container.

Mandatory OSHA Posters and Signs - Safety Blog | Safesite OSHA regulates most workplaces and requires safety signs at most locations where a hazard threatens the safety of a worker. Each safety sign is classified by hazard risk to help determine what sign to use, including DANGER, WARNING, and CAUTION. Implement these key safety sign formats to meet OSHA requirements for safety signage. DANGER

4.7 - Workplace labels | WHMIS 2015 - University of Ottawa created in the workplace, received without a supplier label or transferred into a container that had no labelling. Workplace labels do not require a border or specific wording; they do, however, require the following information: Product identifier (product name matching that on the SDS), Information for the safe handling of the product, and

Post a Comment for "39 workplace labels must be put in place"